Amid rising energy costs, environmental pressures, and the demands of global trade, extending the lifespan of refrigerated containers has become a key challenge for fleet operators. Carrier Transicold responds to these needs by introducing innovative modernization programs and advanced digital solutions that increase equipment reliability, reduce operating costs, and minimize the environmental footprint of transport.

New Challenges in the Global Cold Chain

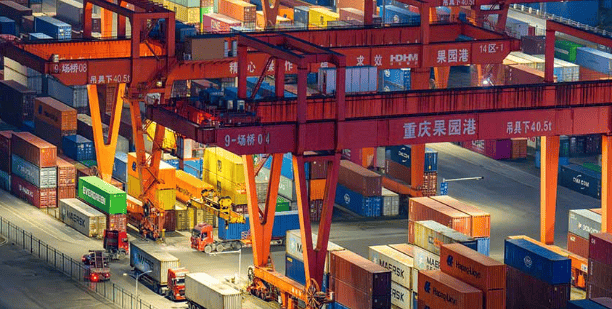

Refrigerated containers (reefers) are an essential element of international trade in food, pharmaceuticals, and chemical products. Maintaining precise and stable temperature conditions is crucial to preserving the quality and safety of transported goods.

However, over time, refrigeration units lose efficiency – they consume more energy, require more frequent maintenance, and generate higher operating costs. Extending the lifecycle of equipment has thus become not only a technical challenge but also an economic and ecological one. In this context, Carrier Transicold, a global leader in refrigeration technology, has developed comprehensive solutions that significantly extend the life of refrigerated containers.

REN Program – “Reefer Enhancement and Next-Life”

One of Carrier Transicold’s key initiatives is the REN Program (Reefer Enhancement and Next-Life), aimed at users of PrimeLINE refrigeration units. The program extends the lifespan of equipment by up to three years through the modernization of key components:

- Replacing compressors with more energy-efficient models,

- Upgrading heat exchangers,

- Modernizing the refrigerant circuit,

- Integrating monitoring and telemetry via Lynx Fleet.

This approach allows operators to reduce the total cost of ownership (TCO) and postpone the need to invest in new units. Importantly, the REN program is compliant with the latest environmental standards and supports CO₂ reduction strategies in refrigerated transport.

Transform Line Modernization Solutions

Another cornerstone of Carrier’s strategy is the Transform Line – a set of modernization solutions for containers, trailers, and railcars. It includes:

- Retrofit kits enabling the installation of the EverFRESH controlled atmosphere system,

- Upgrades improving energy efficiency and operational ergonomics,

- Digital modules integrating older units with modern fleet management systems.

These solutions allow operators to keep older units in service for many years without the costly need to replace them entirely.

EverFRESH – Longer Product Freshness and Equipment Lifespan

The EverFRESH system is another innovation that indirectly affects equipment longevity. By actively controlling the internal atmosphere (oxygen and carbon dioxide levels), the technology slows the respiration of fruits and vegetables, extending their freshness.

More stable temperature conditions and reduced load fluctuations also lead to less wear and tear on refrigeration unit components – compressors, valves, and heat exchangers.

Digital Telemetry and Predictive Maintenance

Modern Carrier Transicold containers are increasingly equipped with the Lynx Fleet system, enabling remote monitoring of refrigeration unit performance. Operators gain real-time access to data such as temperature, energy consumption, operational history, and equipment status.

Through predictive analytics, potential failures can be identified and preventive maintenance scheduled before any component damage occurs. This predictive maintenance approach extends equipment life, reduces downtime, and minimizes the risk of cargo loss.

Benefits for Operators and the Environment

Applying Carrier Transicold technologies delivers multiple benefits:

- Lower operating costs – through modernization and smart energy management,

- Extended container lifecycle – modernizations allow equipment to remain in service for several additional years,

- Improved reliability – predictive maintenance prevents failures,

- Reduced environmental impact – lower CO₂ emissions and less equipment waste,

- Higher resale value – refurbished units retain strong market value.

The Future of Refrigerated Transport

Carrier Transicold’s initiatives reflect a broader trend toward digitization and sustainability in transport. The company continues to develop technologies that not only enhance energy efficiency but also support a circular economy – favoring modernization over the replacement of equipment.

In the coming years, solutions such as REN, Transform Line, EverFRESH, and Lynx Fleet may become standard in the industry, setting new benchmarks for refrigerated container fleet management.

Carrier Transicold demonstrates that innovation and environmental responsibility can go hand in hand with economic efficiency. Through modernization programs and digital monitoring tools, the company effectively extends the lifespan of refrigerated containers, reduces operating costs, and minimizes environmental impact.

In a world where reliability and sustainability are core to competitiveness, Carrier’s strategy exemplifies how technology can support both business and the planet.